Benefits of Polypropylene Webbing

Polypropylene webbing offers a number of benefits over other types of webbing, including:Strength: Polypropylene webbing is very strong, even when wet. It's incredibly durable, making it ideal for heavy-duty applications.

Lightweight: Polypro webbing is much lighter than other types of webbing, such as nylon or polyester. This makes it easier to handle and transport.

Water resistance: Polypro webbing does not absorb water, making it ideal for use in wet environments. This also makes it resistant to mildew and rot.

Chemical resistance: Polypro webbing is resistant to a wide range of chemicals, including acids, bases, and solvents. This makes it ideal for use in industrial applications.

UV resistance: Polypro webbing is resistant to UV radiation, making it ideal for outdoor use. It will not fade or degrade in the sun.

Manufacturing Straps with Polypropylene Webbing

Polypropylene webbing straps can be manufactured in a variety of ways, depending on the specific application. For light-duty applications, the webbing can simply be cut to length for use. For heavy-duty applications, the webbing can be sewn to reinforce it, and used with hook and loop fasteners to make a variety of different configurations.A basic overview of the manufacturing process:

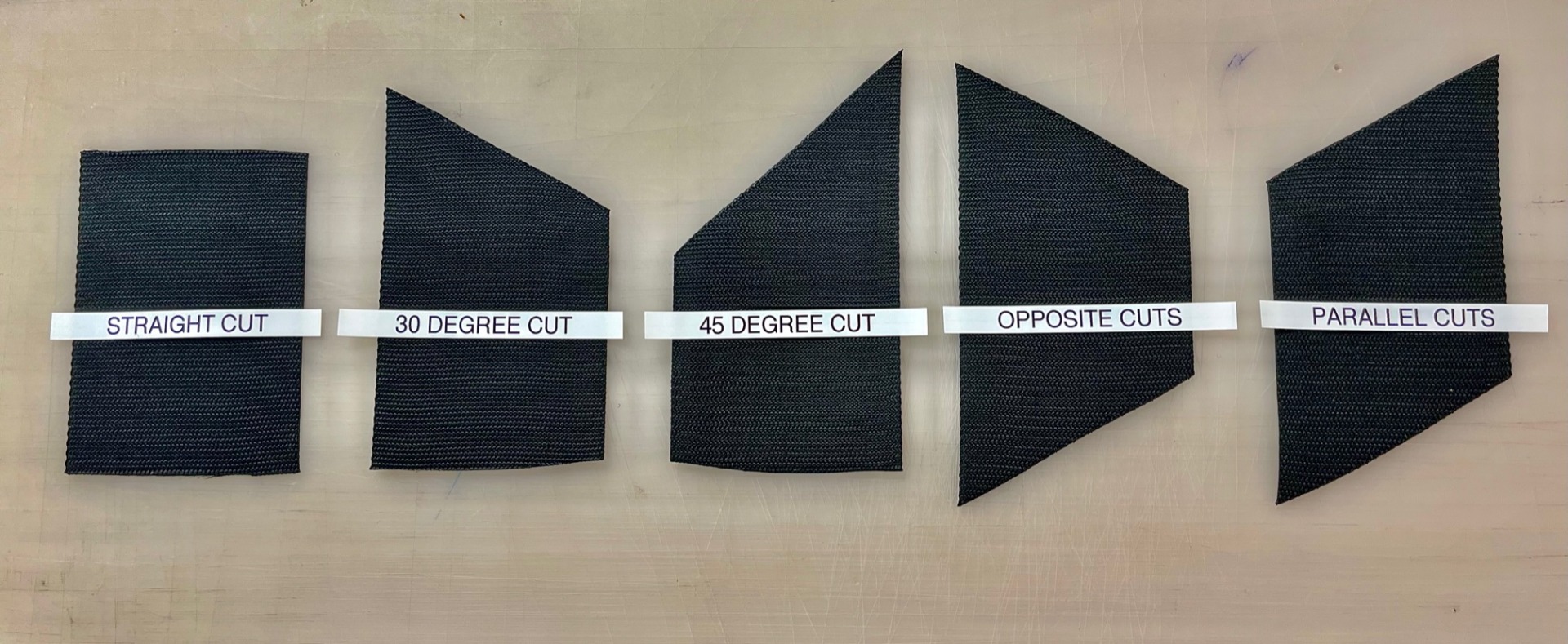

- The desired width of webbing is selected and cut to the desired length.

- The webbing is sewn together, or hook and loop are sewn to it to create a strap that fastens.

- Hardware, such as buckles and D-rings, are sewn into place.

- The strap is inspected to ensure that it meets all quality standards.

Applications for Polypropylene Webbing Straps

Polypropylene webbing straps are used in a wide variety of applications, including:- Cargo tie-downs: Polypropylene webbing straps are ideal for securing cargo to trucks, trailers, and other vehicles.

- Heavy duty lifting slings: Heavy-duty polypropylene webbing straps can be used to create lifting slings for lifting and transporting heavy objects.

- Pet collars and harnesses: Polypropylene webbing is a popular material for pet collars and harnesses because it is strong, durable, and water-resistant.

- Backpack straps: Polypropylene webbing is often used for backpack straps because it is strong and lightweight.

- Military equipment: Polypropylene webbing is used in a variety of military equipment, including ruck sacks, molle bags, and more.

- Industrial applications: Polypropylene webbing is used in a variety of industrial applications, such as conveying systems, packaging, and safety equipment.